The 5 Hidden Costs of Falling Stock in Your Warehouse (And How to Prevent Them)

Falling stock might seem like a small problem — but it can lead to injuries, product loss, downtime, and costly non-compliance. Here's how rack netting can prevent it all.

In a busy warehouse, it’s easy to overlook small risks — until they become big problems.

Falling stock is one of those underestimated risks. One unsecured pallet, one bump of a forklift, and suddenly you’re dealing with damaged goods, injured staff, and halted operations. But the real cost goes far beyond the mess on the floor.

At Zonex Safety, we’ve seen firsthand the hidden impact of falling stock — and how easy it is to prevent. Here are five hidden costs that most operations managers don’t calculate… until it’s too late.

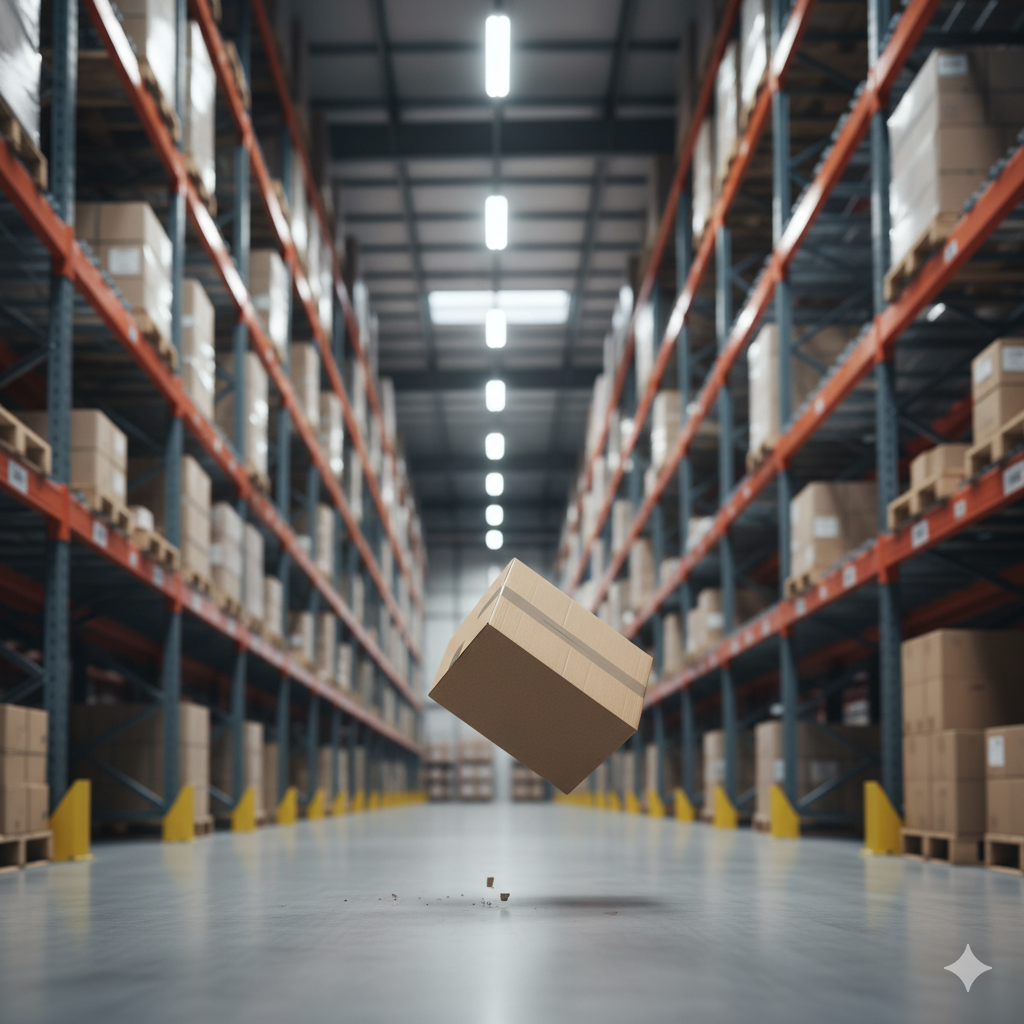

🚧 Problem 1 : Stock Falling from Racking

The Risk:

Unsecured pallets and overhanging stock can fall during forklift movement or due to vibration over time — causing injuries, damage, or downtime.

The Fix:

Install rack netting barriers behind and beside your racking. Zonex Safety nets contain loose or shifted stock, keeping your team and inventory safe.

🦶 Problem 2 : Pedestrian and Forklift Collisions

The Risk:

Shared spaces between machinery and people increase the risk of serious injury or death from collisions.

The Fix:

Use pedestrian barriers, bollards, and clear floor markings to separate traffic zones and walkways. Ensure visibility with convex safety mirrors at blind spots.

⚠️ Problem 3 : Racking Damage from Equipment

The Risk:

Forklift impacts to rack legs or end frames weaken structural integrity, putting the entire racking system at risk of collapse.

The Fix:

Install rack protection guards and end-of-aisle barriers to absorb impact. Train forklift drivers regularly on safe handling practices.

🧯 Problem 4 : Not Meeting Safety Compliance Standards

The Risk:

Failing to comply with AS/NZS safety standards can lead to failed audits, fines, insurance claim rejections, or business closures.

The Fix:

Use a rack safety checklist (we can provide one!) and schedule regular audits. Install certified safety gear like netting, barriers, signage, and anti-slip solutions.

⏱️ Problem 5 : Downtime from Safety Incidents

The Risk:

Even a minor accident can bring operations to a halt — costing hours of productivity, disrupting workflows, and causing missed dispatches.

The Fix:

Prevent accidents before they happen by installing passive safety systems (like Zonex netting), training your team, and maintaining clear visual safety signage across your facility.

Protect your team. Protect your stock. Prevent downtime.

With the right safety systems in place, your warehouse can run smoother, safer, and more efficiently.

Ready to take the next step?

Book a quick call or email us at admin@zonexsafety.com.au — we’ll help you find the right solution for your site